Tirap Colliery

NORTH EASTERN COALFIELDS, COAL INDIA LIMITED

1.0 GENERAL INFORMATION:

- Date of opening; 01/11/1983

- Geological Reserve (in Million Tes as on 31/121/2015)-29.21

- Mineable Reserve ( in Million Tes as on 31/12/2015)-15.68

- Rate of production= 5.10 Lac Tes/annum (approx.)

- Life of the mine= 30 years.(Approx.)

- Number of the seams- Four seams (8 feet, 5 feet, 20 feet, and 60 feet seam).

- Av. Thickness and range (thickness) of the seam-8 feet (1.5 to 2.0 M), 5 feet (1.0 to 2.0 M), 20 feet (5.0-7.0 M) and 60 feet seam (18 to 24 M).

- Av. Inclination of the seam -18⁰ -20⁰.

- Minimum and maximum depth of the working- Min. 110 M, Max. 240 M.

- Known significant restrictions on mining -N.H. 38 runs along the Northern boundary of the mine, Ledo Pani Nullah restricts the extension.

- Powder Factor-6.26.

- Av. drilling rate – 420 holes/day.

1.1 LOCATION:

Tirap Colliery is one of the three operating opencast mine of NEC and has been in the existence since 1983.It is located in the Makum Coalfields of Assam. The mine is well connected by road and railways. The N.H 38 runs along the Northern part of this Colliery. The nearest town is Ledo and is about 3 km to the West. Margherita Township which is the area H.Q of NEC is situated at a distance of 10 km from the mine. Nearest domestic airport Mohanbari (Dibrugarh) is at a distance of 93 km from the mine.

1.2 PHYSIOGRAPHY:

area lies along the Northern flank of the Patkai range and is characterized by rugged topography due to presence of hills. The area experiences humid short summer, prolonged rainy season and a fairly cold winter. Annual average rainfall ranges between 300-425 cm and the monsoon extends from April to September. The dry spell generally lies between December and March.

1.3 GEOLOGY:

Major Geological disturbances have their effects on the method of working. The coal bearing horizons of Tertiary formation belong to the Eocene and Oligocene age. The Coalfields extend along the Northern front of the Naga –Patkai hill range. The coal seams have drained into folds (Anticline) plunging E- N.E.with the folds running more or less S.E – S.W. The North Limb is dipping from 200 – 230 towards North and South limb is dipping 100 – 110 towards South. At present, workings are concentrated along the south limb.

1.4 COAL SEAMS:

The adjoining strata with coal seams exhibit alluvium soil, sand stones, carbonaceous shale and clays. In all there are 4(four) seams known in this area namely: 8 ft., 5 ft., 20 ft. and 60 ft. seams. Out of these four seams 60 ft. and 20 ft. Seams are the only major seams known to be consistent and have been exploited extensively. Thickness of these two coal seams is 46.5-31.95m and 4.5-11.09m respectively.

1.5 METHOD OF WORK:

Mechanized mining with Hydraulic excavator and Dumper combination is being practiced here. Drilling is done by mechanized drills and blasting is conducted under proper supervision.

1.6 LEASE AREA : 342 Hectares

1.7 RESERVES :

| Sl No | Geological Reserves (In Million Te) 31.12.2015 | Mineable Reserves as on 31.12.15 (In Million Te) | Total Coal Extracted Since Inception (In Million Te) | Stripping Ratio |

|---|---|---|---|---|

| 1 | 29.21 | 15.68 | 12.9 | 1 : 7.20 |

1.8 COAL QUALITY:

| ANALYSIS | 60 FT. SEAM | 20 FT. SEAM |

|---|---|---|

| Ash % | 2.90-4.00 | 3.00-41.4 |

| Moisture % | 2.60-4.10 | 1.60-4.70 |

| Volatile Matter % | 43.30-44.50 | 30.10-45.70 |

| Fixed Carbon % | 47.40-51.20 | 33.40-51.20 |

| Sulphur % | 1.40-3.50 | 5.60-6.80 |

| C.I. | 22-25 | 20-23 |

| GCV( kcal/kg ) | 7710-7865 | 6470-6895 |

2.0 PARTICULARS OF KEY OFFICIALS:

| Agent | Mr S.S. Gaggar |

| Manager | Mr. Rupjyoti Baruah |

| Colliery Engineer | Mr. M.P.Dutta |

| Safety officer | Mr. U.K .Mukherjee |

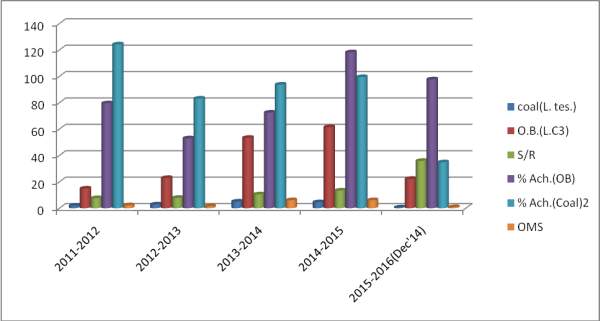

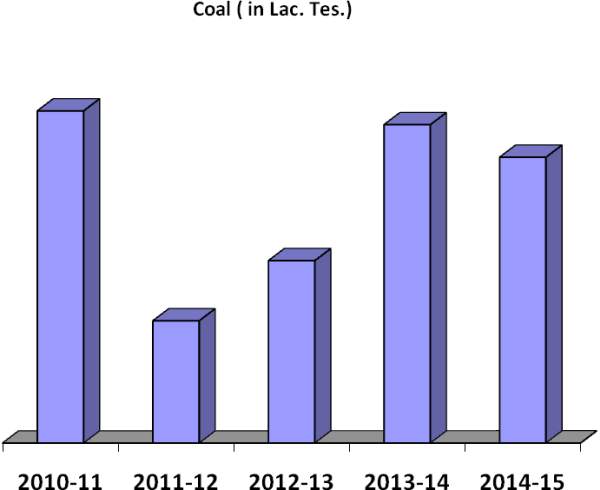

PRODUCTION:

| Financial Year | Coal ( in Lac. Tes.) | O.B. ( in Lac cu.m) | S.R. | % Achievement | O.M.S. | |

|---|---|---|---|---|---|---|

| OB | COAL | |||||

| 2010-11 | 5.3 | 24.37 | 4.6 | 61.03 | 106 | 6.11 |

| 2011-12 | 1.95 | 14.95 | 7.67 | 79.56 | 124.2 | 2.27 |

| 2012-13 | 2.91 | 22.96 | 7.89 | 53.01 | 83.14 | 1.56 |

| 2013-14 | 5.08 | 53.41 | 10.51 | 72.51 | 93.73 | 6.12 |

| 2014-15 | 4.58 | 61.48 | 13.42 | 118.22 | 99.49 | 6.11 |

| 2015-16(up to Dec’15 | 0.62 | 22.27 | 35.92 | 97.7 | 34.83 | 0.9 |

3.1 PRODUCTION PERFORMACE CHART OF LAST FIVE YEAR

Chart A

Chart B

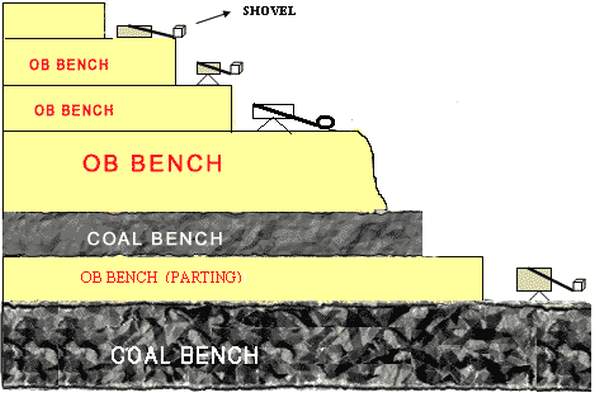

4.0 MINE WORKINGS

4.1 METHOD OF WORK:

| Sl. No. | Particulars | Description/Status |

|---|---|---|

| Combination | Hyd. Shovel-Dumper | |

| Mechanization | Fully mechanized mine with 110 mm dia drills, 1.8-3.3 m3 Hyd. Shovels & 18 m3 dumpers. | |

| Bench Height | 12 metres | |

| Bench Width | 3 times the width of Bench Height | |

| Bench Cleanliness | Maintained with the exclusive deployment of Dozer. | |

| Working Bench | Free from loose material etc. up to 3 mts. | |

| Footpath | One number provided from surface to pump house | |

| Fences | As per requirement whenever necessary | |

| Mine Planning | Approved Mining plan as per the guidelines of CMPDI | |

| Spoil Banks | Being maintained in bench formation (9 Mts.) bunds provided at the edges. Tree plantation at the slope | |

| Mine Drainage | Bench slope mildly sloping away. A nullah of adequate size provided encircling the quarry. Drainage provided along the haul road to avoid road cutting. | |

| Haul Road | Well maintained at every place. |

4.2 GENERAL LIGHTING

| Sl. No. | Particulars | Description/Status |

|---|---|---|

| Dumping Places | Towers fitted with HPMH lamps are provided in all dumping areas. | |

| Loading Point/Coal Stock | Towers fitted with HPSV lamps are provided at loading point. | |

| All Critical Points, Like Pumping, Drilling Etc. | Adequate lights are provided. One portable lighting tower with high pressure Sodium Vapor Lamps are provided. |

|

| Haul Roads | MH&SV Lights are provided all along the dumper haul roads. |

5.0 SAFETY DRIVE TIRAP COLLIERY

| Safety drive on “Haul Road Maintenance” including its parapet walls, turning point, bends, width of haul road, water spraying arrangements etc. | 08/06/15 to 09/06/15 | Mr.B.B.Sahoo Dy,Manager(Min.) |

|---|---|---|

| Safety Drive on “Dumping operation at O.B. Dump” covering i)Duty of spotter ii)Safety beam position iii)Movement of vehicles | 09/07/15 to 10/07/15 | Mr.M.P. Dutta, Colliery Engineer. |

| Safety Drive on maintenance, safe operation of HEMM and lighting covering the i) Maintenance schedule of HEMM. ii) Safety equipment of HEMM iii) Road sign, Symbols etc. iv) Lighting/Illumination | 11/09/15 to 12/09/15 | Mr.R.Kalita, Asstt.Manager(EXC) |

| Safety drive on bench width, height edge berm, dressing, drainage system etc. | 15/11/15 to 16/11/15 | Mr. Uttam Mukherjee, Dy,Manager(Min.) |

6.0 MANPOWER

MANPOWER (AS ON 01/02/2016)

| Sl. | Particulars | Male | Female | Total |

|---|---|---|---|---|

| 1 | Departmental | 310 | 17 | 327 |

| 2 | Contractual West Patch | 235 | Nil | 235 |

| Total | 545 | 17 | 562 |

7.0 SAFETY MEASURES TAKEN AT TIRAP COLLIERY:

The following effective steps taken to improve the safety standards in the mine:

Due care is taken for the safety of the men and machines working in the mines. All possible measures are adopted in advance for the safety in mines. To prevent recurrence of accidents all the recommendations of findings of the accident enquiries are being implemented after deliberation in the safety committee meeting (Statutory body). All workers are being trained as per need to make them aware with the changing new technologies and method of workings with due consideration to the safety norms.

All the provisions of the Mines Act & Rules, Coal Mines Regulations, etc. and the Circulars issued there under in this regard are being complied with to ensure occupational safety for the employees/workers at their workplaces.

To enhance & ensure safety standards for the workers employed in mines, there exist different types of Safety Forums such as, Workmen Inspectors and Pit Safety Committee (with workers active participation), Bipartite and Tripartite Safety Committee at Area and Corporate level.

All the recommendations/suggestions made by the Standing Committee on Safety in coal mines, National Safety Conference, Court of Inquiries, Safety Boards, Tripartite, Bipartite & Pit Safety Committees are implemented forthwith.

Senior officers are inspecting the mines to check safety status. Suggestions given by them to improve the safety status of mines are implemented immediately. Code of Safe Practices are framed for critical operations and implemented.

To enhance and maintain the safety awareness among workers Safety Fortnights and special safety drives are observed in mines. Awareness and Safety talks in each shift (every Wednesday to Contractual employee of M/S ANE) are being practiced on regular basis to develop a safety culture in accordance of “Code of Safe Practices”.

The protective appliances against the danger of fire, dust, noise, air pollution and visibility have been introduced in addition to normal protective safety appliances being supplied to the workers. This will further help in preventive control of safety hazards.

All the accidents were enquired into by the ISO & DGMS officials and based on their findings and with the approval of competent authority the disciplinary action was taken against the persons found responsible for the accident. Also based on the findings of enquiry report, ISO circulars were issued for taking immediate corrective measures.

Risk Assessment for the mines has been done either externally or internally (by individual unit management). All the risk prone areas identified and accordingly Safety Management Plan has been prepared for time framed implementation.

Before monsoon, a high level review is done to assess the status of monsoon preparation with apprehended danger due to surface waters and accordingly action plan is prepared for implementation & monitoring. The rescue station / room etc. have been fully equipped with round the clock emergency services available within 5 Km. of the mine.

The initial training is imparted to all new entrant and refresher training to all employees as per statute. Thrust on training and retraining of Supervisors, HEMM operators and contractor’s workers was maintained as a strategy to reduce accidents in opencast mines and at surface of mines The major area of risk is assessed for each mine and preventive actions are also provided to educate workers. DO’s and DON’Ts with posters publicity and propaganda is adapted. All the accidents affected persons is called before the Pit Safety Committee Meeting and the cause of accident as well as the mistake / defect in the system is analyzed to avoid such accidents. Training and refresher training is provided to all the workmen. All the resources are made available at the worksite with its know-how to avert accidents in future.

7.1 ANNUAL SAFETY WEEK AWARDS

| Year | Nature of Awards | Presented by | Remarks |

|---|---|---|---|

| 2012 | Mine Machinery | Annual Oil & Coal Mines Safety Week Celebration | Second |

| VT, PME, and General Safety Consciousness | Second | ||

| Surveying & Maintenance of Statutory Records and Registers | Second | ||

| 2013 | VT, PME, and General Safety Consciousness | Second | |

| Accident Free Mine 2012 | Winner | ||

| First-Aid competition | Winner | ||

| 2014 | Overall performance | First | |

| VT, PME, and General Safety Consciousness | First | ||

| Surveying & Maintenance of Statutory Records and Registers | First | ||

| Accident Free Mine- 2013 | First | ||

| Mine Machinery | First | ||

| 2015 | Mine Machinery | First |

8.0 STATUTORY PERSONNELS

| Sl No | Discipline | Designation | Manpower on roll as on 01.02.16 |

|---|---|---|---|

| Mining Executives | Manager | 1 | |

| Safety Officer | 1 | ||

| ACM(1st Class-5), ACM(2nd Class-1) | 6 | ||

| Mining Supervisor | Overman | 8 | |

| Mining Sirdar | 25 | ||

| Engineer | Engineer | 4 | |

| Survey | Manager(Survey)-1,Sr.Surveyor-1 | 2 | |

| Electrical | Supervisor | 1 | |

| Mechanical | Supervisor | 4 | |

| Workman Inspector | Sr.Overman-1,Supervisor(El-1,Mech-1) | 3 |

9.0 WELFARE AMENITIES

| Sl. No. | Particulars | Description/Status |

|---|---|---|

| CANTEEN | 1 No. | |

| REST SHELTER | 05 No. | |

| LATERINES & URINALS | 05 No. | |

| FIRST-AID ROOM | Not applicable | |

| DISPENSARY | At colony site | |

| AMBULANCE VAN | 1 No. | |

| FIRST-AID STATION | 03 No. | |

| FIRST-AID KIT | Provided | |

| FIRST-AID PERSONNELS | 46 Nos. | |

| DRINKING WATER | Chlorinating plant at the quarry pithead/Office premises/ Pit head earthen pots kept at suitable places, Water cooler& Aqua guard is provided at mines canteen & Office. Water Bottle/ Chagall’s to all face workers. |

10.0 MEDICAL EXAMINATION:

| 2015 | Particulars | Description/Status | |

|---|---|---|---|

| Examination | Departmental | Contractual | |

| IME | 13 | 73 | |

| PME | 88 | 2 |

11.0 TRAINING: A Group Training Center consisting of Office Rooms, Lecturer Room, Model Room Work Shed, Laboratory etc.

| Particulars | Description/Status | Particulars | |||

| TRAINING STAFF | TRAINING STAFF | ||||

| V.T. OFFICER | One | V.T. OFFICER | |||

| TRAINING INSTRUCTOR | One | TRAINING INSTRUCTOR | |||

| OTHER TRAINERS | As and when required, other officials are involved for imparting training. | OTHER TRAINERS | |||

| TRAINING SCHEDULE | TRAINING SCHEDULE | ||||

| 2016 | Training | Departmental | Contractual | 2017 | |

| Initial | 7 | 103 | |||

| Refresher | 26 | Nil | |||

| Special | 20 | Nil | |||

| VARIOUS TRAINING AIDS PROVIDED IN THE V.T.C | T.V with C.D player, Slide Projectors, Over head projectors, Charts and Tables, Live models, Tools and tackles. | VARIOUS TRAINING AIDS PROVIDED IN THE V.T.C |

12.0 ACCIDENTS STATISTICS

| YEAR | FATAL | SERIOUS | REPORTABLE | MINOR |

|---|---|---|---|---|

| 2012 | Nil | Nil | Nil | Nil |

| 2013 | Nil | Nil | Nil | Nil |

| 2014 | Nil | Nil | Nil | Nil |

| 2015 | Nil | Nil | Nil | Nil |

13.0 ENVIRONMENT PROTECTION

| Sl No. | Particulars | Description/Status | |

|---|---|---|---|

| 1 | Air: Drilling | Wet operated drills are used. | |

| Haul Roads & other places | Water sprinkling is done as routine work constantly round the clock at all the haul roads and other strategic points. | ||

| Survey of air borne dust | Pollution monitoring & Analysis is done by engaging an external Agengy approved by Pollution Control Board, Assam. Reports of the same done by the agency are sent to the Board on regular basis. | ||

| 2 | Water: Quality of mine water and drinking water | Parameters Untreated Treated pH 3.3 6.5 Suspended Solids 191 84 BOD 87 26 COD 397 219 Oil & grease 5.13 1.97 Ammonical Nitrogen 22.34 5.37 | |

| Abetment measures of mine water | An Effluent Treatment Plant of adequate capacity has been provided and maintained wherein the effluent water is mixed with lime& soda ash and thereafter the treated water is subjected to flocculation & further sedimentation before being discharged into Ledopani Nullah. | ||

| 3 | Noise: Noise survey | Monitoring of noise is done by engaging an external agency. The noise level is found to be well within the permissible limits. Reports of the same done by the agency are sent to PCBA on regular basis. | |

| 4 | Vibration | Well within the permissible limits | |

| 5 | Land reclamation & Rehabilation measures: Area available for reclamation and rehabilitation. | 97.95 Ha. | |

| Actual area reclaimed | 80.45 Ha. | ||

| 6 | Afforestation (within mining lease area): Area available for afforestation Area utilized for afforestation Sapling planted for 2014-15 Percentage (%) of survival | 63.64 Ha. 39.06 9000 Nos 65% | |

| 7 | Environmental management: Equipment | Pollution monitoring & Analysis is done by engaging an external Agency approved by Pollution Control Board, Assam. | |

| Frequency of monitoring | Quarterly | ||

| Provision of staff | Environmental officer | one | |

| Field supervisor | One | ||

| Other facilities | Effluent Treatment Plant is maintained. Water Tankers with capacity of 9000 Ltrs each are maintained for routine spraying to control dust pollution. Controlled blasting is done with NONEL to minimize ground vibration so that undesired cracks are not developed in the surface. Plantation of 9000 trees have been done to control surface soil erosion. Gully plugging and check dams and toe walls are provided to prevent surface soil erosion. Garland drains are provided to direct surface run off to the mine pit. |

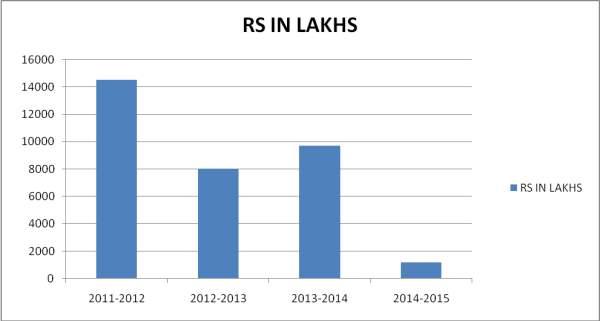

14.0 COST PERFORMANCE (2014-15) :

| Parameters | Last Year (2014-15) | |

|---|---|---|

| O.M.S.(Tes) | 6.11 | |

| E.M.S. | Rs. 3201.90 | |

| Amount (Rs. in Lacs) | CPT(Rs.) | |

| Profit/Loss | 1191.6 | 2346.6 |

15.0 PROFIT CHART (IN LAKHS RS.)